- Yokohama-shi Top Page

- Living and Procedures

- Housing and Living

- Waste and recycling

- Introduction of facilities

- Incineration Plant

- Kanazawa Factory

- Incineration plant waste incineration

Here's the text.

Incineration plant waste incineration

Last Updated March 7, 2019

Overview of the Kanazawa Plant

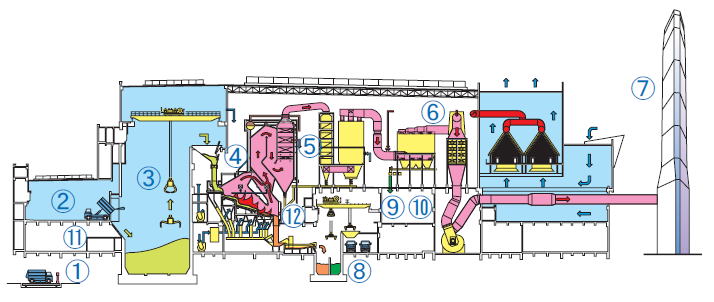

Overview of each equipment (Click the number below to see the outline of each equipment)

(1) Measurement equipment

(2) Input stage

(3) Garbage pit crane

(4) Waste incinerator

(5) Boiler equipment

(6) Exhaust gas treatment facilities

(7) Chimney

(8) Ashpit crane

(9) Fly ash treatment equipment

(10) Steam turbine generator

(11) Wastewater treatment facilities

(12) Central Control Room

(1) Measurement equipment

Measure the weight of the garbage collected by the collection vehicle.

Measurement equipment

(2) Input stage

This is a place where the garbage collected by the collection vehicle is put into the garbage pit. The other side of the door is the garbage pit.

In addition, the inside of the input stage is kept at negative pressure, so that odors do not leak out.

Inspection of incoming materials for business-related waste is conducted here.

Input stage

(3) Garbage pit crane

The garbage pit is a facility that temporarily stores the incoming garbage and responds to changes in the amount of incoming garbage and the amount of incineration.

A garbage crane is a facility for grabbing garbage and putting it into an incinerator. There are three garbage cranes at the Kanazawa Plant, which are operated almost automatically at night.

Operation of garbage cranes

Video![]()

Garbage pits and garbage cranes

(4) Incinerators during operation of waste incinerators

An incinerator is a device that burns garbage continuously. The garbage in the incinerator burns on a table called a stoker (fire grid) and turns into ash. The stoker is divided into three parts: dry stoker, combustion stoker, and later burning stoker. First, the garbage is dried on the dry stoker, then flames are burned on the combustion stoker and burned vigorously, and finally fully incinerated on the later combustion stage stoker.

The incineration temperature is at a high temperature of 850-950°C.

State of waste incineration

Video![]()

Inside the incinerator

Inside the incinerator during operation

(5) Boiler equipment

A boiler is a device like a large water heater that generates steam. It is removed with increased pressure and temperature (approximately 400°C, 3.9 MPa). The extracted steam is used as a heat source required for incineration of garbage, used for power generation at a steam turbine generator, and is also used as a heat source for supplying heat to a residual heat utilization facility (Linetsu Kanazawa).

Boiler equipment

(6) Exhaust gas treatment facilities

The exhaust gas generated by the incineration of garbage contains harmful substances such as hydrogen chloride, sulfur oxides, nitrogen oxides, and mercury.

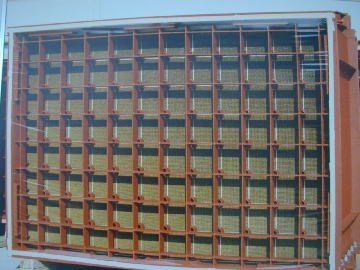

The filtered dust collector (bug filter) is a cloth bag-shaped filter, and by blowing slaked lime and activated carbon just before the filter, slaked lime neutralizes acid gases such as hydrogen chloride (HCl) and sulfur oxides (SOx) in the exhaust gas by slaked lime, and activated carbon absorbs and removes mercury (Hg) and dioxins.

After that, ammonia water vaporized gas is blown into the exhaust gas, and nitrogen oxides (NOx) are decomposed and removed using a denitrification catalyst.

Bug filter

Denitrification equipment

(7) Chimney

This is where the treated exhaust gas is released into the atmosphere. Inside the chimney with a height of 130m, a total of three steel chimneys pass from each incinerator.

※In winter, white smoke can be seen from the chimney, which means that water vapor in the exhaust gas cools to the outside air and looks white.

Chimney

(8) Ashpit crane

The ash from the incinerator is cooled by an ash extrusion device, transported by an ash conveyor, and stored in an ash pit. In addition, ash (fly ash) collected by a filtration type dust collector is processed by a fly ash treatment facility and then transported and stored here.

The ash crane plays the role of putting ash into melting equipment and loading it into ash loading vehicles.

The ash loaded on the ash carry-out vehicle is transported to a landfill site.

Ash pit ash crane

(9) Fly ash treatment equipment

The fly ash treatment facility processes fly ash collected by a filter dust collector (bug filter). The heavy metal fixer, cement, and water are mixed with a kneader to treat the heavy metal so that it does not elutate, and then sent to the ash pit.

Fly ash treatment equipment

(10) Steam turbine generator

Steam of about 400 ° C is produced from waste heat generated by burning garbage. Most of this steam is sent to a steam turbine generator to produce electricity. The generator has a power generation capacity of up to 35,000 kW, which is equivalent to the power consumption of approximately 80,000 households.

Steam turbine generator

(11) Wastewater treatment facilities

Wastewater treatment equipment is a facility that cleans wastewater from each facility in the factory by coagulation sedimentation treatment and filtration treatment.

Water that has been treated for wastewater is basically reused in factories.

Wastewater treatment facilities

(12) Central Control Room

The Central Control Room is a place to monitor and operate the operation status of all equipment at the Kanazawa Plant. A major feature of this incineration plant is that each device is automatically operated by a computer. The monitor on the table shows all operating conditions in the factory at a glance. In addition, about 70 video cameras are installed in the factory, which can be monitored.

Operation monitoring is a shift work and is performed 24 hours a day without a break.

Central Control Room

Inquiries to this page

Kanazawa Plant, Resources and Waste Recycling Bureau Proper Treatment Planning Department

Telephone: 045-784-9711

Telephone: 045-784-9711

Fax: 045-784-9714

Email address: sj-kanazawakojo@city.yokohama.lg.jp

Page ID: 255-273-398