- Yokohama-shi Top Page

- Living and Procedures

- Housing and Living

- Waste and recycling

- Introduction of facilities

- Incineration Plant

- Factory tour

- Overview of Waste Incineration Plant Facilities (Japanese version)

Here's the text.

Overview of Waste Incineration Plant Facilities (Japanese version)

Last Updated August 24, 2020

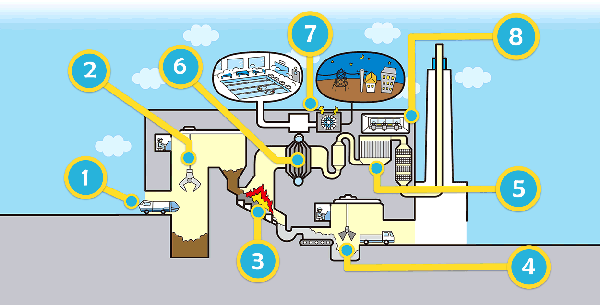

This is a factory equipment map. Click the name of each facility below to see the details.

1-input stage

Collection vehicles that have collected combustible waste drop garbage into the "garbage pit" where garbage is temporarily stored at the "input stage".

Since hundreds of collection vehicles enter and exit each day, the input stage is monitored in the input monitoring room so that there is no accident and improper garbage is not brought in.

The "input door" detects a collection vehicle and automatically opens and closes it.

The collection truck that the loading platform lifts the garbage directly from the input door to the garbage pit.

When manually dropping garbage from a car whose loading platform does not lift, work safely by receiving garbage in a dumping box and then dropping garbage in the way of the slide so that people do not fall into the garbage pit. If you find an inappropriate carry-in there, you can prevent carry-in.

▲ Click to start the video. (There is no sound.)

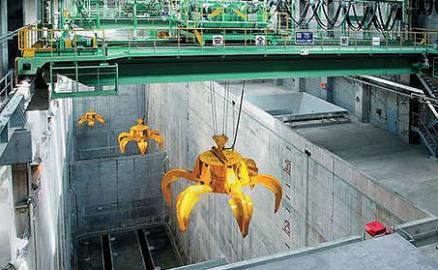

2 Garbage pits and garbage cranes

The "garbage pit" is a large space where the garbage brought by the collection truck is once collected.

Grab the garbage with the "garbage crane" and put the garbage into the "incinerator" from the "garbage pit".

At this time, the important thing is to stir the garbage and make it uniform before putting it in.

Recyclables and incombustibles are finely sorted at the time of garbage collection, so in principle only "combustible garbage" is transported to waste incineration plants. Among them, "combustible garbage" is mixed with "flammable garbage" like kitchen garbage and "flammable garbage" like paper.

Therefore, with a garbage crane, stir evenly (garbage stirring and make the garbage more flammable.

The "garbage crane" is operated by qualified operators.

The cranes continue to move without resting 24 hours a day, while also performing autonomous driving as needed, such as at night.

▲Click to start the video. (There is no sound.)

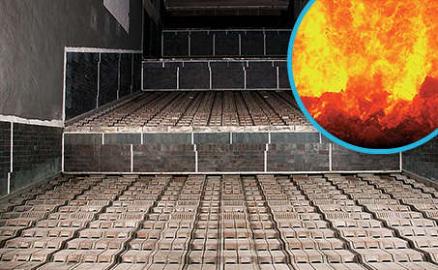

3 Incinerator

The garbage thrown into the "incinerator" burns itself as fuel.

Therefore, once the garbage is ignites when the incinerator starts up, no fuel will be used until the incinerator is stopped.

In addition, by continuing to burn at a high temperature of 850-950 ° C, odor is removed and the generation of dioxins is suppressed.

In addition, the air required for garbage incineration is taken in from the "garbage pit" that stores garbage, and it is devised so that the odor of garbage does not come out of the garbage pit.

▲Click to start the video. (There is no sound.)

4 ash pit ash crane

The ash pit is a place to store ash generated by incineration.

The ash from the incinerator is transported by the "ash conveyor" and stored in the "ash pit".

In addition, soot and dust removed by the exhaust gas treatment facility are transported by another conveyor, processed with chemicals, etc., and stored in a dedicated ash pit.

Grab the ash with the "ash crane" and load it on a truck carrying the ash.

The ash loaded here is transported to the Waste landfill.

In order to make effective use of limited landfill over the long term, it is necessary to reduce waste, including thorough sorting.

▲Click to start the video. (There is no sound.)

5 Exhaust gas treatment facilities

Exhaust gas treatment equipment is equipment that removes harmful substances from exhaust gas generated during incineration of waste.

First, the exhaust gas is cooled rapidly with a temperature reduction tower to prevent the resynthesis of dioxins.

After that, through the exhaust gas through a device called a "bug filter", dust, which is fine dust in the exhaust gas, and dioxins adsorbed to chemicals, are removed.

In addition, harmful components contained in exhaust gas are removed by chemicals such as slaked lime, activated carbon, and ammonia.

The exhaust gas treated in this way is released from the chimney into the atmosphere.

In Yokohama City, we manage exhaust gas at numerical values that are stricter than the regulatory standards stipulated by law.

In addition, we strive to ensure the safety of local residents by publishing the measurement results of exhaust gas components after treatment.

▲Click to start the video. (There is no sound.)

6 boiler

A boiler is a device that uses the heat generated during incineration of garbage to boil water and make steam.

The generated steam is sent to a steam turbine generator and used for power generation.

In addition to being used for air conditioning, heating, hot water supply, etc. in the incineration plant, it is sent to an adjacent residual heat utilization facility to use it as a heat source for heated pools and bathing facilities.

▲Click to start the video. (There is no sound.)

7 Steam turbine generator

The steam turbine generator is a facility that converts high-temperature and high-pressure steam generated by the boiler into electrical energy.

The electricity produced is used in incineration plants and nearby facilities, and the remaining electricity is sold to electric utilities.

In order to increase the power generation of steam turbine generators, it is necessary to improve the combustion efficiency of incineration plants.

For this reason, Yokohama City is asking for cooperation such as draining water-rich kitchen garbage and drying pruned branches before disposing of garbage.

▲Click to start the video. (There is no sound.)

8 Central Control Room

Waste incineration plants operate 24 hours a day without a break.

For this reason, in the Central Control Room, operators operate and monitor the incineration plant every day 24 hours a day.

Images of cameras installed at various locations in the incineration plant are displayed on the LCD monitor and monitored.

The monitor in front of the operator displays real-time data such as temperature, pressure, and exhaust gas concentrations.

Depending on these circumstances, automatic computer control and manual operation by the operator can monitor and remote control of on-site equipment, ensuring optimal combustion at all times.

▲Click to start the video. (There is no voice

★ The whole flow

▲Click to start the video. (There is no sound.)

Inquiries to this page

Facility Division, Resources and Waste Recycling Bureau Proper Treatment Planning Department

Telephone: 045-671-2518

Telephone: 045-671-2518

Fax: 045-664-9490

Email address: sj-shisetsu@city.yokohama.lg.jp

Page ID: 814-113-262