- Yokohama-shi Top Page

- Living and Procedures

- Housing and Living

- Waste and recycling

- Introduction of facilities

- Incineration Plant

- Tsuzuki Plant

- Explanation of facilities at the Tsuzuki Plant

Here's the text.

Explanation of facilities at the Tsuzuki Plant

Last Updated April 10, 2019

Please click on each item or scroll down.

- Input stage

- Garbage pit

- Garbage crane

- Inside the incinerator

- Boiler

- Temperature Reduction Tower

- Bug filter

- Chimney

- Ash conveyor

- Ash pit

- Ash crane

- Central Control Room

- Turbine generators

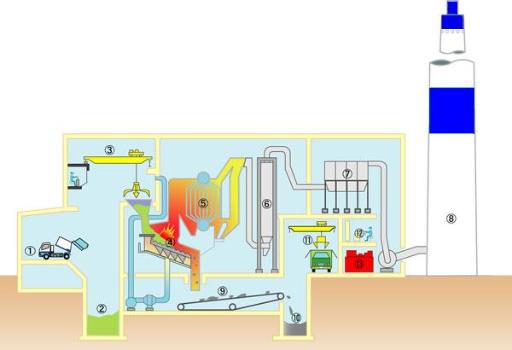

1.Input stage

Kannon door type hydraulic drive type, totaling 14 gates

After measuring the weight of the garbage, the collection truck puts the garbage into the garbage pit here.

The Tsuzuki Plant mainly carries garbage from "Tsuzuki Ward , Aoba Ward, Kohoku Ward and part of Midori Ward."

2.Garbage pit

15,000m3(5,000m3×3)

The Tsuzuki Plant has three 5,000m3 pits, which can store approximately 3,600 tons of garbage.

Garbage can be stored in the garbage pit instead of burning immediately.

The odor of the garbage pit is blown into the incinerator as combustion air, and the odor is decomposed.

3.Garbage crane

Ceiling crane with hydraulic open/closed polyp bucket

The garbage is put into the incinerator by the garbage crane.

One grab is about 6 tons, and you can grab garbage for about 3 collection vehicles.

There are three garbage cranes that can be operated at the same time.

The bucket of the garbage crane is wide and 4.9m wide and weighs about 6.8 tons.

4.Inside the incinerator

Mitsubishi-Martin Waste Incinerator (400t/24h)

The temperature inside the incinerator is more than 850 ° C, and garbage ignites naturally.

When starting up the incinerator, heat it with a gas burner at least 300 degrees and then put in garbage.

After that, the temperature is gradually increased to 850°C.

At the Tsuzuki Plant, there are three incinerators that can burn 400 tons of garbage a day, and they are used in order while maintaining them.

5.Boiler

Gas cooling boiler "Single furnace type two-body natural circulation type (with carbon-saving and overheater)

63.1t/h、Max2.25MPa、3,675m2

In boilers, steam is made using the heat generated when burning garbage.

It is the same principle as boiling water with a kettle. Most of the steam produced is used in turbine generators.

It is also used as a heat source for heated pools and baths by sending it to the next facility that uses air conditioning and hot water in the factory, as well as for hot water pools and baths.

6.Temperature Reduction Tower

113,970Nm3/h, inlet 380 degrees

Since the bag filter cannot withstand temperatures above 250 degrees, it uses water here to lower the temperature.

We use reused water in the factory for the water used.

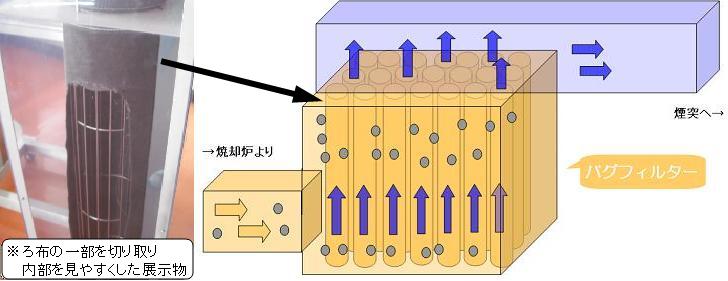

7.Bug filter

Filter type dust collector (gas volume: 136,620Nm3, 250-degx MAX, 0.01g/m3N or less)

The dust in the exhaust gas is removed through a filter called "rofu".

The filter cloth is wrapped in a cylindrical skeleton, and there are 1760 cylinders in a single bag filter.

Since the filter cloth deteriorates at high temperatures, the temperature of the incoming exhaust gas is always kept below 200 degrees.

8.Chimney

3-cylinder flue made of steel, concrete outer cylinder support collective chimney height 130m, cylinder body diameter 2.45m

Exhaust gas is released into the atmosphere, so it does not affect the surroundings.

In winter, you can see white smoke, which is the moisture contained in the exhaust gas.

This is because it is cooled by touching the atmosphere and becomes water vapor.

At night, a red lamp is lit so that the airplane can check the chimney.

9.Ash conveyor

Electric motor drive endless chain (overreturn type)

The incinerated ash from the incinerator is transported to the ash pit by an ash conveyor.

When garbage is burned, the volume is about 1/20 and the weight is about 1/5.

The treatment is carried out hygienically and stably.

10. Ash pit

1,140m3(380m3×3)

The ash pit is a place where ash is temporarily stored, and there are three pits.

Fly ash obtained from a dust collector is solidified with cement and sent to the ash pit.

11. Ash crane

Ceiling crane with hydraulic clamshell bucket (4.8t)

The ash is loaded on a truck with an ash crane and transported to landfill.

About 6.5 tons of ash is loaded per truck.

12. Central Control Room

Operation of the incinerator is carried out in the central control room.

All factory data is collected in the control room and centralized management is performed.

Since the incinerator operates 24 hours a day, staff is stationed in the control room 24 hours a day.

13. Turbine generators

Impulsive 13,530kVA, 13,000 kW, 6,600 V

Turns the turbine with the power of steam produced in the boiler.

The turbine is equipped with a generator, which generates electricity by turning the generator. Remember the light of a bicycle, it is the same principle that the light turns on when the tires turn around.

Electricity is used in factories and is also sent to facilities that use residual heat. Still, the surplus electricity is sold to electric power companies. The amount of electricity sold will be more than 400 million yen per year.

Inquiries to this page

Tsuzuki Plant, Resources and Waste Recycling Bureau Proper Treatment Planning Department

Telephone: 045-941-7911

Telephone: 045-941-7911

Fax: 045-941-7912

Email address: sj-tsuzukikojo@city.yokohama.lg.jp

Page ID: 295-324-044